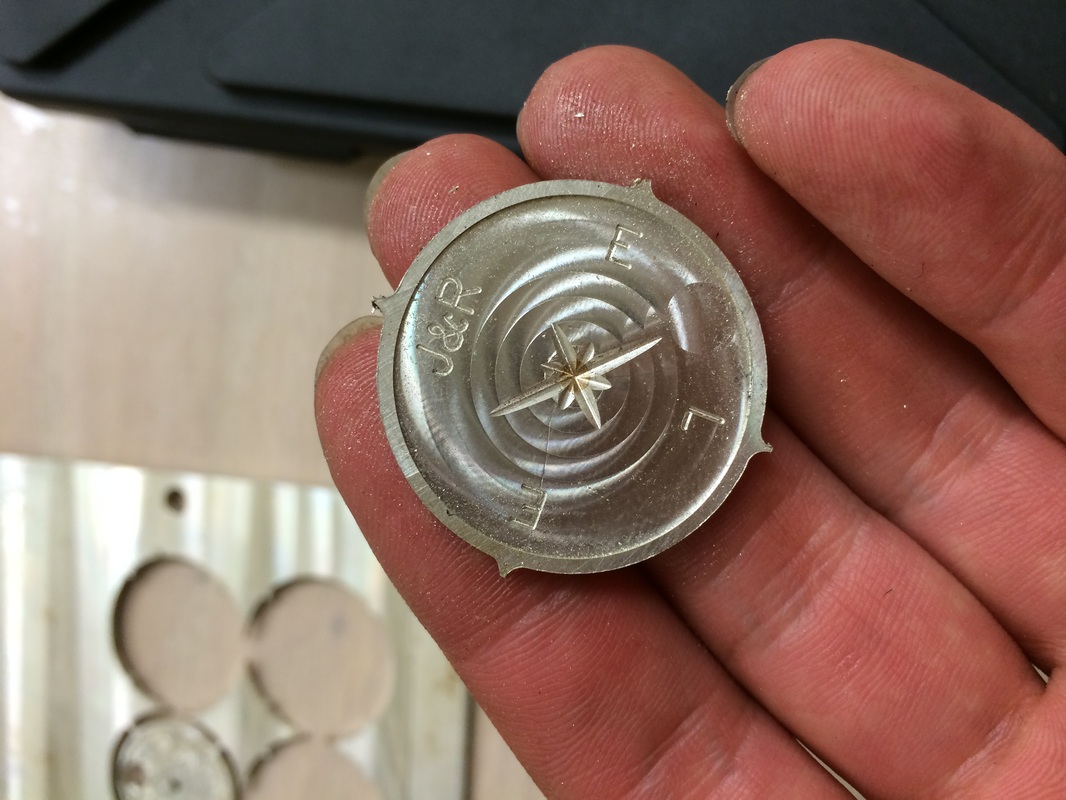

Silver Coin: Congrats, Jeremy!

Goal: design and manufacture a coin made of silver and gold to celebrate my brother's coming marriage in September 2014.

Materials:

Processes:

Materials:

- Plate of 11 gauge fine silver

- 10 gauge 14k gold wirel

- 1/4", 1/8", and 3/64" square end mills

- 1/16" ball nose endmill for surfacing

- 45 deg single lip engraving tool

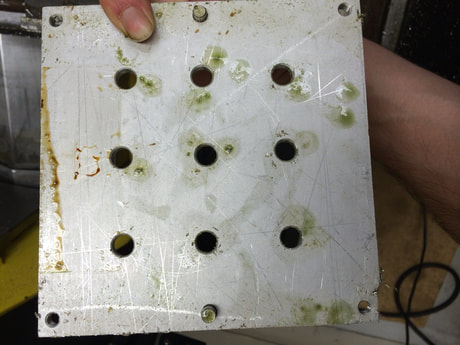

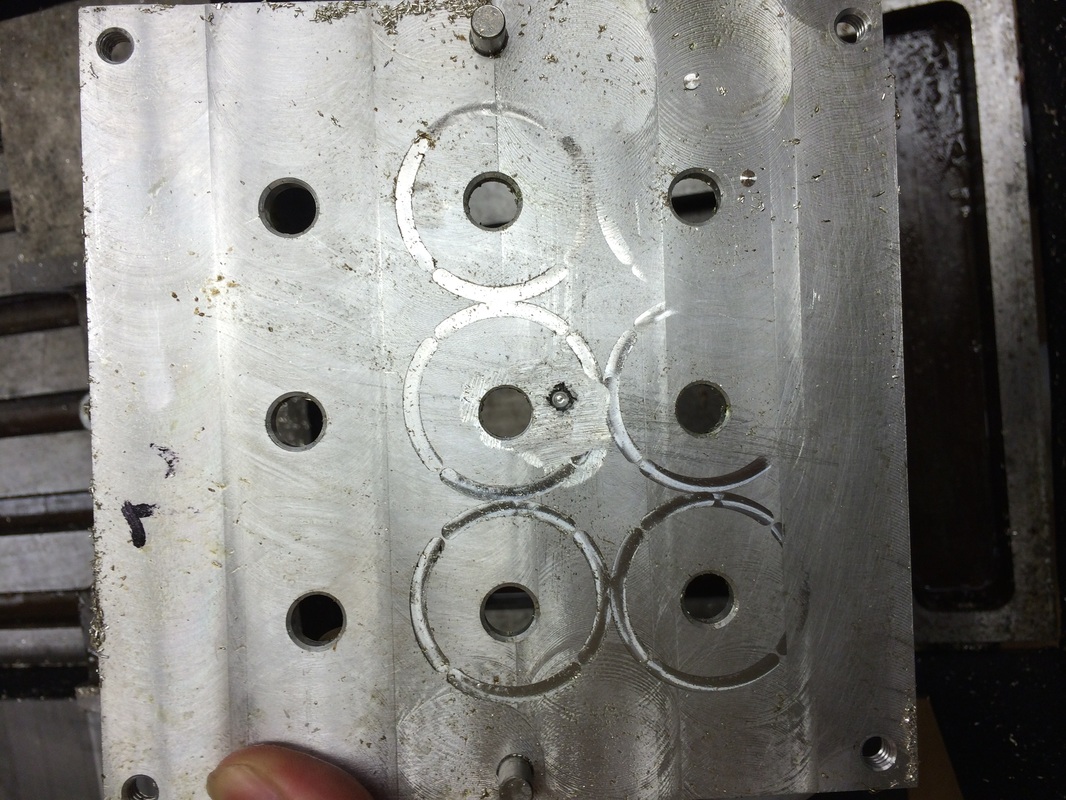

- Aluminum plate (for fixture)

Processes:

- CAD work (SolidWorks)

- CAM work (MasterCAM)

- CNC machining and fixture design

the process

|

|