Candlestick Magic: an Adjustable Candlestick Holder

Goal: design and build the ultimate candlestick holder that is easy to use and stylish. Different sized silicone rubber inserts ensure a snug, repeatable fit with standard candle sizes. A heavy wood and metal base with an organically shaped arm support a turned aluminum top.

Materials:

Processes:

Materials:

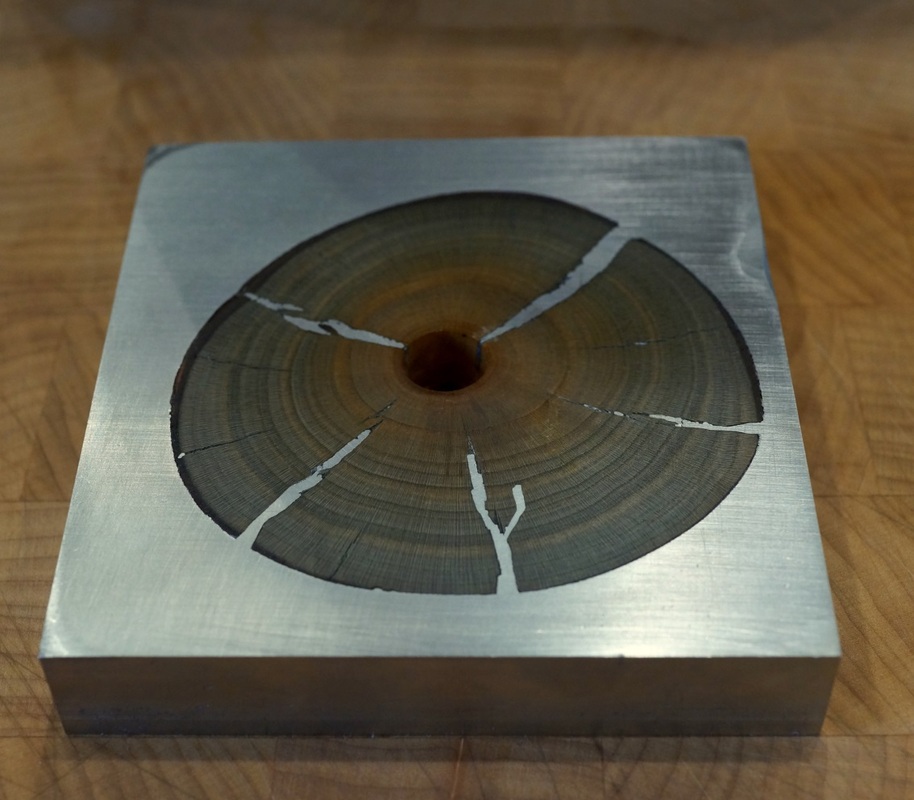

- Slice of oak (from firewood)

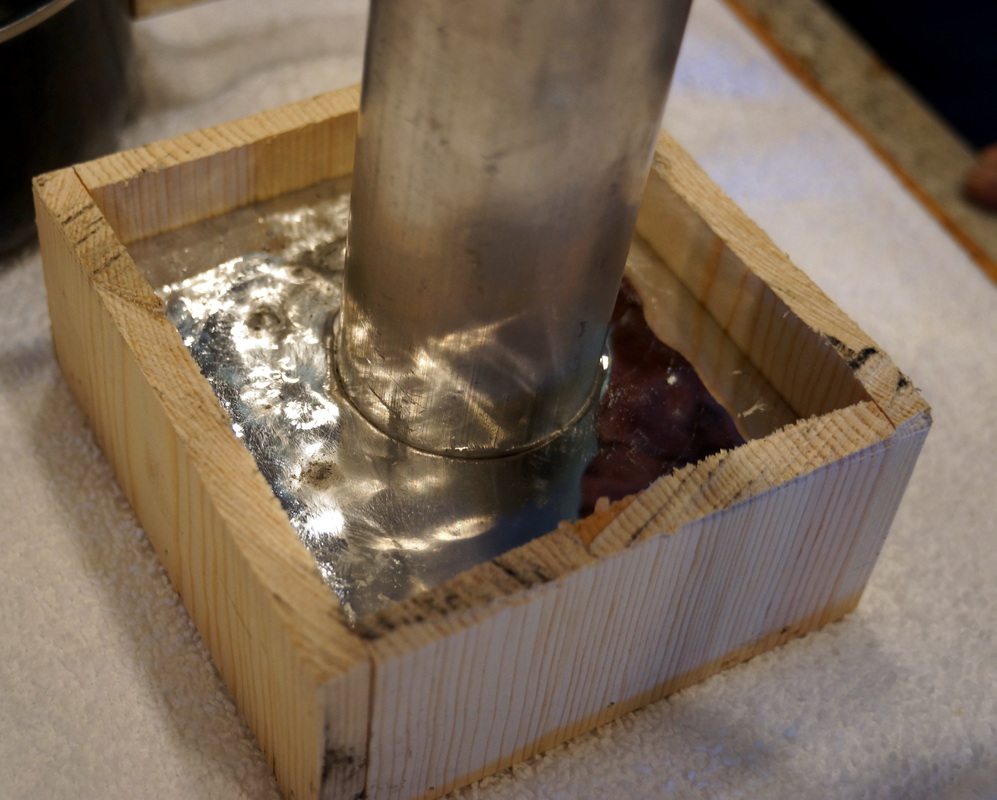

- Low melting point bismuth alloy

- Polyester resin

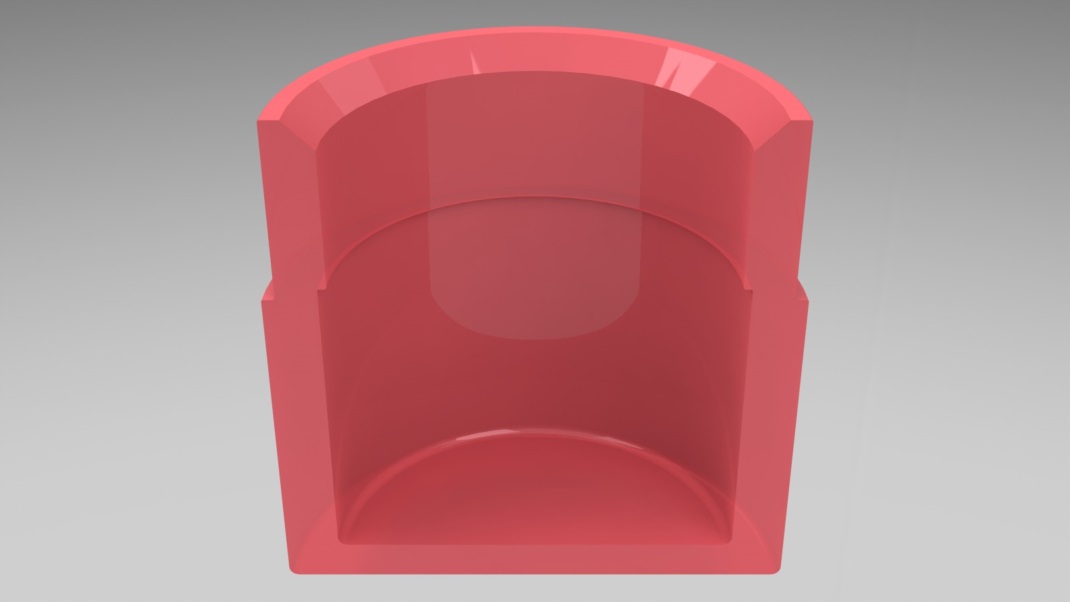

- Urethane rubber (for mold making)

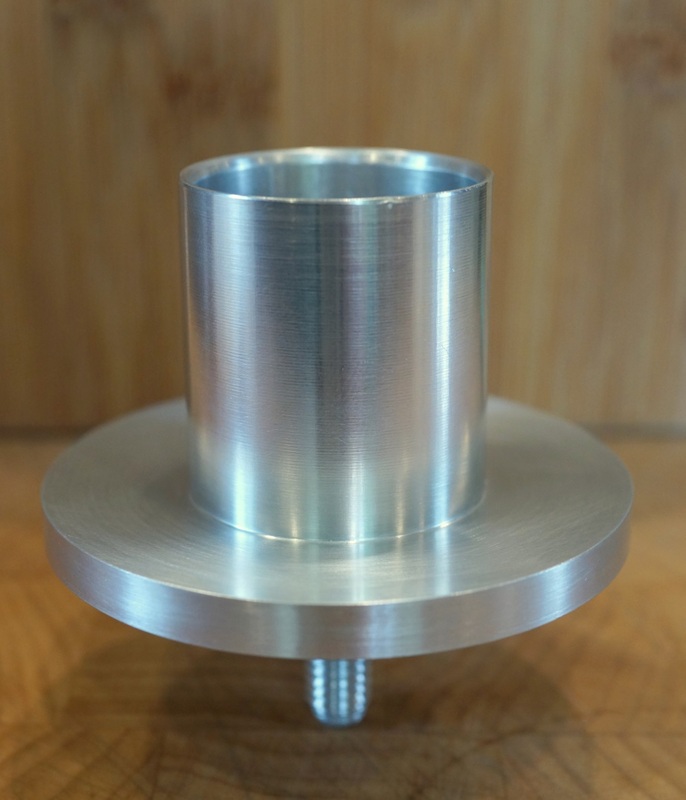

- Aluminum rod (for turning)

- RTV silicone rubber (shore 40A)

- Delrin rod (for mold making)

Processes:

- Mold making and pouring (for polyester and silicone parts)

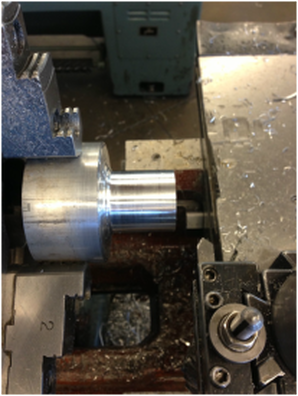

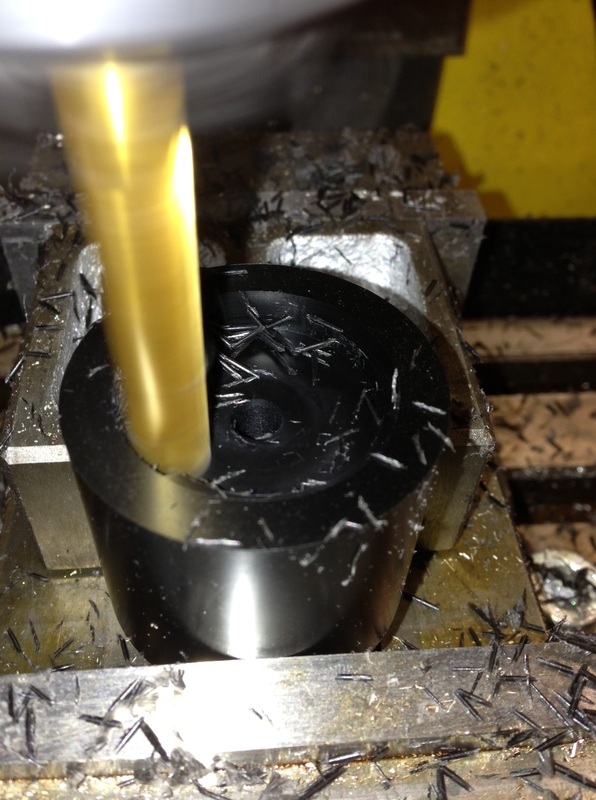

- Turning of aluminum top and threaded brass inserts

- Metal casting

|

|

|