Automated Greenhouse: an Arduino Adventure

UPDATED August 2023

|

|

In the Spring of 2023, after nearly 10 years of uninterrupted service, our automated greenhouse (as detailed below) was destroyed by a water leak in the misting line. Rather than patchwork repair my original system (which was admittedly looking like sun-bleached rats nest at this point), we decided to take the opportunity to rebuild from scratch, with the help of POP Manufacturing (my day job). This time, I'd make the system "industrial strength" by:

|

The Original System (used 2013-2023)

Goal: retrofit a greenhouse to autonomously monitor and control interior temperature and humidity.

Result: The final product works to automatically open and close 6 roof vents using 8" stroke linear actuators, open/close side louvers, turn on/off an ventilation fan, turn on/off a 1 gallon per hour misting system, and turn on/off a 240V, 5kW heater. Current temperature and humidity conditions are continuously monitored and are shown on a wall-mounted iPhone that is also used to display and adjust temperature and humidity set points for the system.

Materials:

Processes:

Result: The final product works to automatically open and close 6 roof vents using 8" stroke linear actuators, open/close side louvers, turn on/off an ventilation fan, turn on/off a 1 gallon per hour misting system, and turn on/off a 240V, 5kW heater. Current temperature and humidity conditions are continuously monitored and are shown on a wall-mounted iPhone that is also used to display and adjust temperature and humidity set points for the system.

Materials:

- Awesome low-tech greenhouse (already built by BC greenhouse)

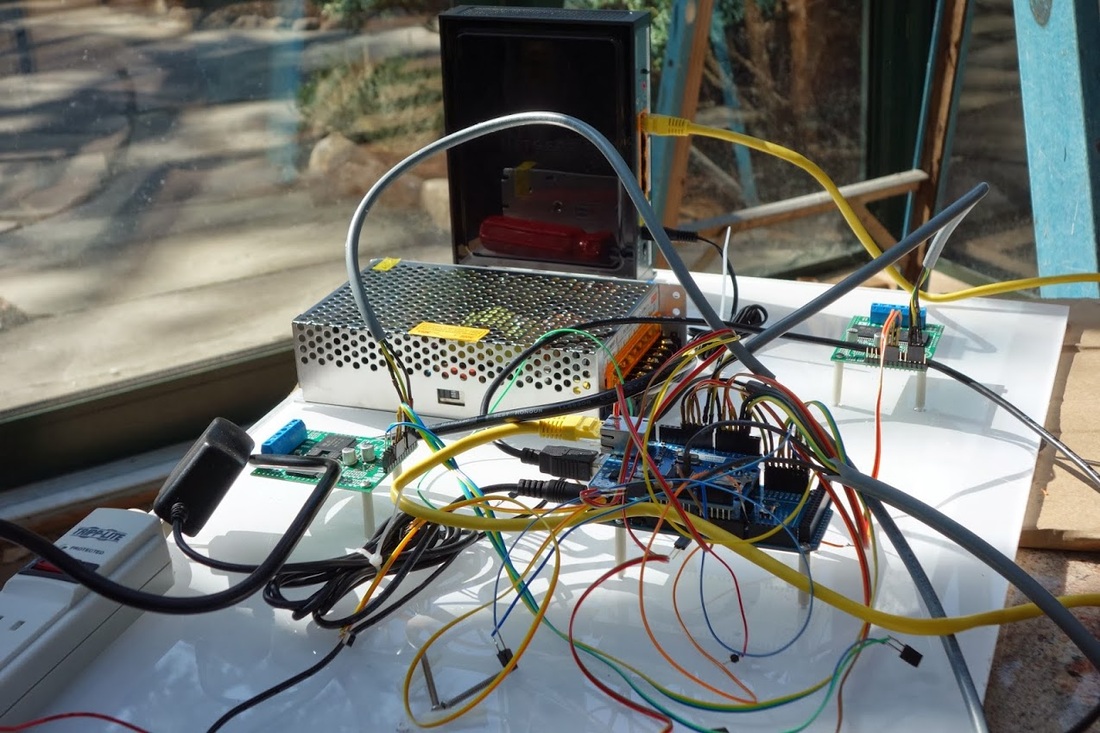

- Arduino Mega

- 8" linear actuators (to open roof vents)

- Pololu dual motor driver boards x3

- 5kW heater

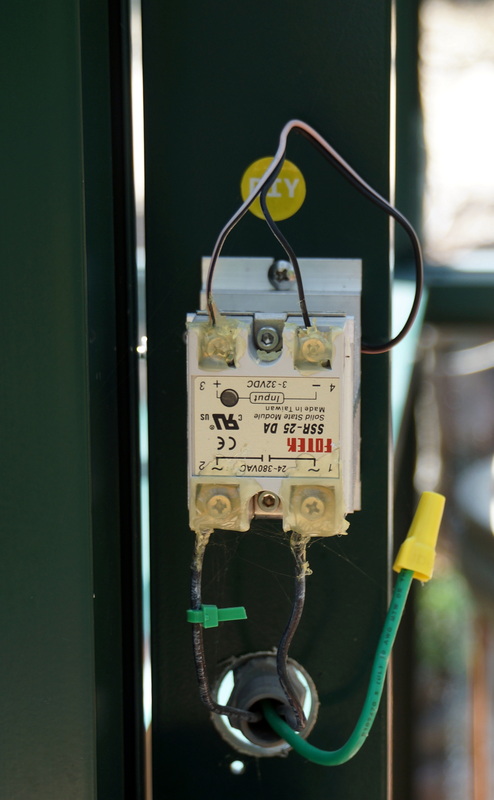

- High-current solid-state relays

- Wireless router

- Patio misters

- Solenoid valve (for water flow)

- Old iPhone

- 12V DC power supply

- Lots of additional electrical components

Processes:

- Arduino programming

- CNC Fabrication (motor mounts and actuator arms)

- Circuit design and protoboard soldering

- Networking and debugging